How do visual inspection equipment identify high quality rubber seals?

Rubber sealing ring, a rubber product for static or dynamic sealing, made of rubber material, elastic and resistant to wear. The main function of rubber sealing ring is to prevent liquid or gas leakage in mechanical equipment, pipeline joints or other devices, while also preventing dust, moisture and other external substances from entering the system to protect equipment from damage.

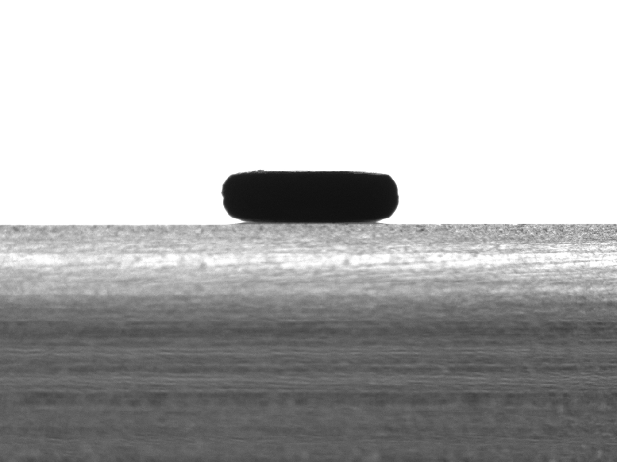

The rubber sealing ring leads to appearance and dimensional defects in the production process such as excessive glue, tip, inner and outer diameter, thickness, etc. Rubber sealing ring visual inspection equipment is recommended. The detection efficiency can reach about 350 pieces per minute.

The rubber sealing ring visual inspection equipment is used to detect the appearance quality and defects of the rubber sealing ring. Using computer vision technology and image processing algorithm, automatic appearance inspection of rubber seals is carried out to ensure product quality and production efficiency.

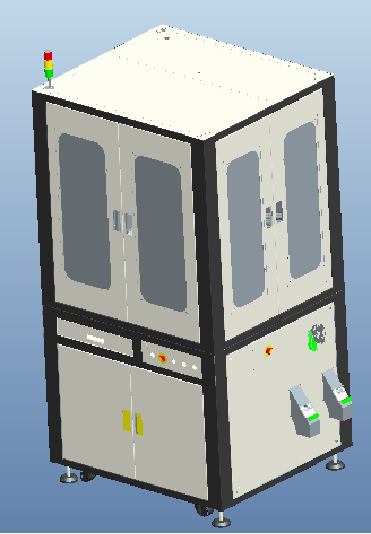

Equipment characteristics

High-precision detection: It can accurately detect various defects on the surface of the rubber seal ring, such as cracks, bubbles, bumps and so on.

Rapid detection: The equipment can quickly detect the seal ring, improve production efficiency and quality control level.

Automatic classification: Automatic classification of qualified and unqualified products according to the test results, reducing manual intervention.

Multi-angle inspection: The rubber seal can be inspected from different angles to ensure comprehensiveness and accuracy.

Data recording and analysis: Equipment can record and analyze inspection data to help manufacturers improve production processes and product quality.

Equipment composition and main organization

Visual inspection software

Industrial computer

display

Industrial camera

Camera adjustment module

Industrial lens

illuminant

Servo motor

Control system

PLC motion collaboration

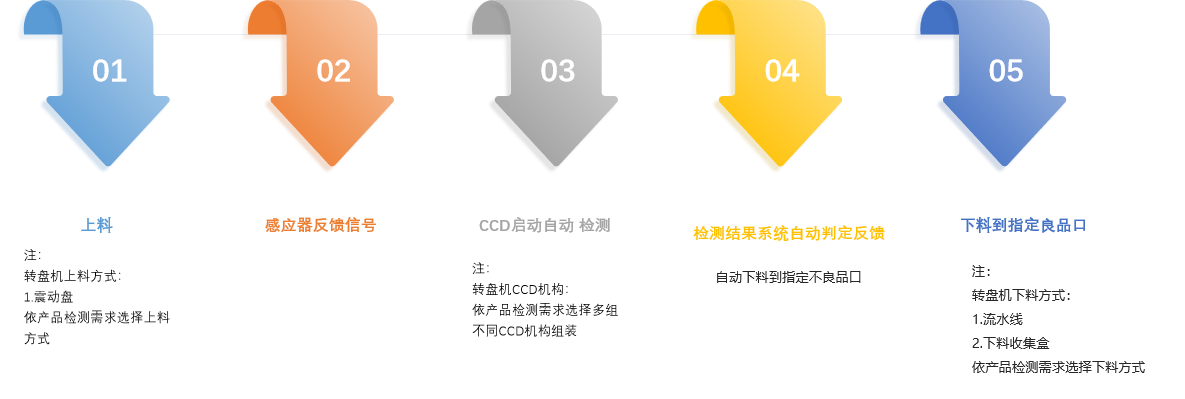

Equipment inspection process

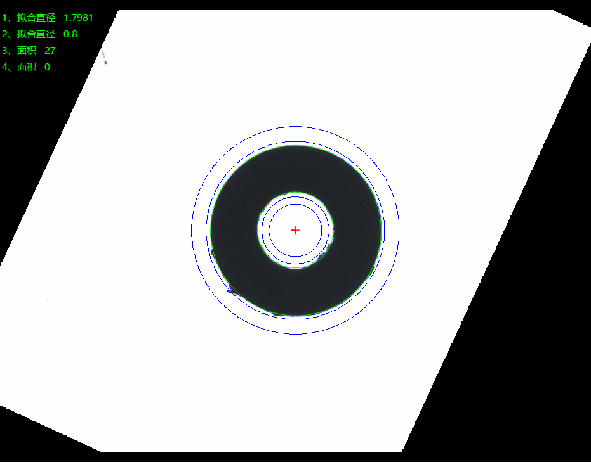

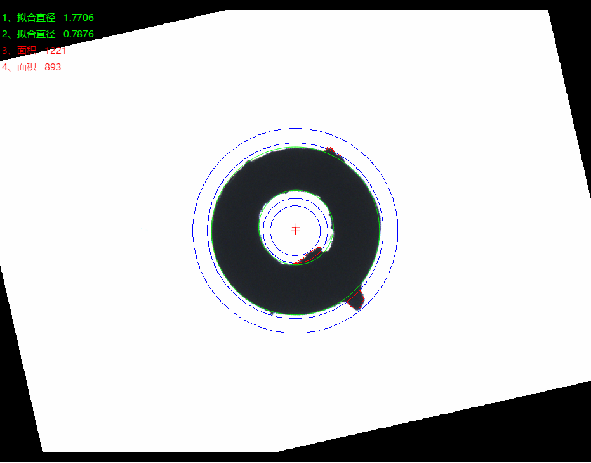

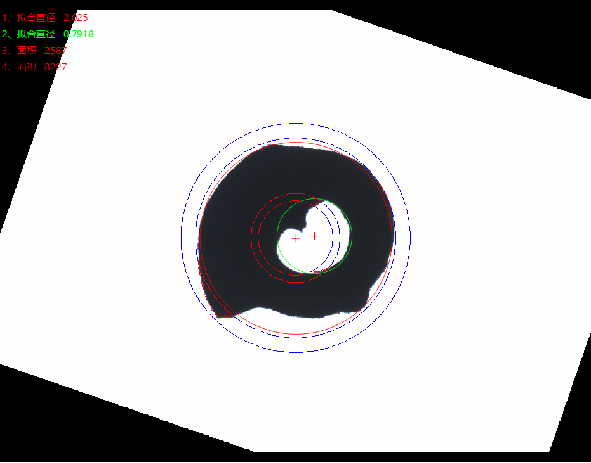

Detection effect

Good product analysis chart

Can realize the tip detection

Multiple material detection

System installation requirements

Inspection space for equipment placement: When installing standard inspection equipment for Siptech Vision inspection systems, it is necessary to ensure sufficient space for installation of equipment.

Ambient temperature: 0-50 degrees Celsius;

Air humidity: below 90% RH;

Electronic interference: Provide a place for the device with less electronic interference.

Power supply: AC 220V, 50Hz, power consumption < 1KVA.

-

Service hotline

13077808017